Wood Material Choose

Slicethinner's Diverse Wood Processing Techniques

How can various materials be combined into a single piece of furniture? With its advanced wood processing equipment, Slicethinner easily produces common wooden materials and can combine composite materials with each other, including metal parts, glass, leather, and fabric. As a technically mature and customer-oriented professional furniture manufacturer, Slicethinner is an indispensable partner for your market expansion.

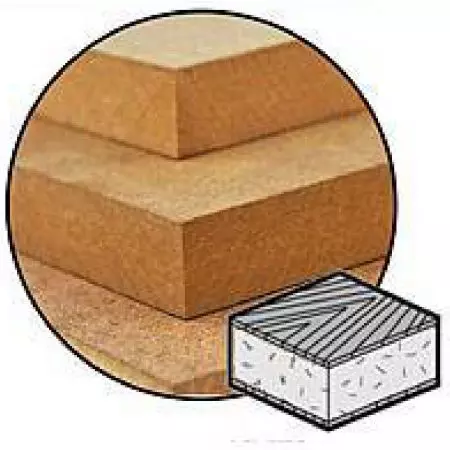

Melamine Faced Chipboard (MFC)

Composition: Melamine faced chipboard is made of wood shavings, wood chips, and resin compressed under high pressure, with a decorative melamine paper on the surface. This decorative paper is pre-soaked in melamine resin and laminated onto the chipboard surface under high pressure and temperature, creating an attractive and durable surface.

Advantages:

1. Aesthetics: MFC is available in various colors, patterns, and wood grains, offering rich decorative effects.

2. Wear-resistant, scratch-resistant, and stain-resistant: The surface is solid, with good wear, scratch, and stain resistance properties.

3. Easy to clean: The surface is smooth and easy to clean and maintain.

4. Economical: Compared to other types of panels, MFC is more reasonably priced.

Disadvantages:

1. Poor water resistance: Due to the water-absorbing nature of the chipboard base material, MFC has relatively weak water resistance.

2. Lower environmental friendliness: The production process may involve harmful substances such as formaldehyde, which can impact the environment and human health.

Common Applications: MFC is widely used in furniture manufacturing, cabinets, wardrobes, shelves, office furniture, etc. Due to its wear, scratch, and stain resistance properties, it is especially suitable for wear-resistant applications such as office desktops and kitchen cabinets.

Medium Density Fiberboard (MDF)

Composition: Medium density fiberboard is a man-made wood product made of wood fibers and resin compressed under high pressure. It is created by breaking down wood into fine fibers, mixing them with synthetic resin (such as urea-formaldehyde resin), and then forming a smooth, dense panel under high temperature and pressure.

Advantages:

1. Smooth surface: MDF has a smooth surface and uniform texture, making it suitable for painting, veneering, or applying paper.

2. Good machinability: Fiberboard is easy to saw, chisel, and carve, making it ideal for processing into various shapes.

3. High stability: MDF has good dimensional stability, making it resistant to warping and suitable for large furniture.

4. Economical: Compared to natural wood, MDF has lower costs and higher utilization rates.

Disadvantages:

1. Poor water resistance: MDF is prone to water absorption and swelling, making it unsuitable for damp environments.

2. Lower environmental friendliness: The production process may involve harmful substances such as formaldehyde, which can impact the environment and human health.

3. Lower compressive strength: Compared to solid wood, MDF has weaker compressive strength, making it less suitable for load-bearing structures.

Common Applications: MDF is widely used in furniture manufacturing, cabinets, wardrobes, shelves, office furniture, and home decorations. Due to its good machinability, it is especially suitable for fine carving or painting applications. However, due to its poor water resistance, it is not recommended for use in damp environments or outdoor spaces.

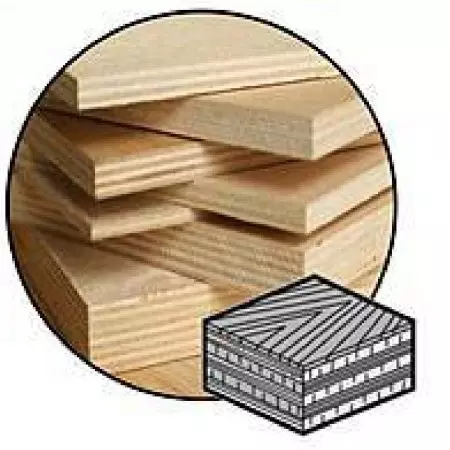

Veneer Core Plywood

Composition: Plywood is made up of several layers of veneer (thin wood slices) stacked alternately and glued together. The grain direction of each veneer layer is perpendicular to the adjacent layers, which helps increase the strength and stability of the plywood. The surface layer of plywood is usually made of high-quality veneer, providing an attractive and durable appearance.

Advantages:

1. High strength: Due to the alternating arrangement of veneers, plywood has higher strength and rigidity, as well as superior bending and compression resistance.

2. Good stability: Plywood has excellent dimensional stability and strong resistance to deformation.

3. Lightweight and durable: Plywood is relatively light in weight and has good durability and a long lifespan.

4. Attractive appearance: The surface veneer is of higher quality, providing a beautiful natural wood grain appearance suitable for high-quality furniture and decorations.

Disadvantages:

1. Higher cost: Compared to other panel materials, plywood is more expensive.

2. Limited environmental friendliness: The production process of plywood may involve harmful substances such as formaldehyde, which can impact the environment and human health.

Common Applications: Plywood is widely used in furniture manufacturing, cabinets, wardrobes, flooring, wall panels, decorative panels, building structures, and other areas. Due to its high strength, stability, and attractiveness, it is particularly suitable for high-quality furniture and interior decorations. However, it is essential to choose products with low formaldehyde emissions to minimize the impact on the environment and health.

Lumber Core Plywood

Composition: Lumber core plywood is composed of a solid wood core (usually made from cheaper wood) and several layers of veneer (thin wood slices). The solid wood core is sandwiched between two or more layers of veneer and glued together. The grain direction of the veneers is perpendicular to the adjacent layers, which helps increase the strength and stability of the plywood. The surface layer of lumber core plywood is usually made of high-quality veneer, providing an attractive and durable appearance.

Advantages:

1. Stronger load-bearing capacity: Compared to other types of plywood, lumber core plywood has a better load-bearing capacity due to its solid wood core.

2. Good stability: Lumber core plywood has better dimensional stability and resistance to deformation.

3. Attractive appearance: The surface veneer is of higher quality, providing a beautiful natural wood grain appearance suitable for high-quality furniture and decorations.

Disadvantages:

1. Higher cost: Compared to other panel materials, lumber core plywood is more expensive.

2. Heavier weight: Due to its solid wood core, lumber core plywood may be heavier than other types of plywood.

3. Limited environmental friendliness: The production process of plywood may involve harmful substances such as formaldehyde, which can impact the environment and human health.

Common Applications: Lumber core plywood is mainly used in furniture manufacturing, cabinets, wardrobes, flooring, wall panels, decorative panels, and other areas. Due to its stronger load-bearing capacity and attractiveness, it is particularly suitable for high-quality furniture and interior decorations. However, it is essential to choose products with low formaldehyde emissions to minimize the impact on the environment and health.

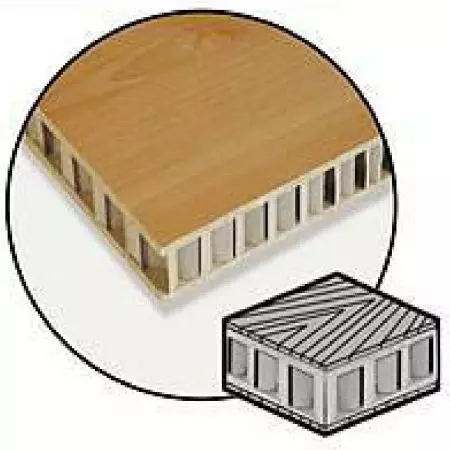

Honeycomb Board

Composition: Honeycomb board is a lightweight and high-strength panel material inspired by the structure of natural honeycombs created by bees. It consists of a paper core with a honeycomb structure and two surface layers (usually made of paper or thin wood slices). The honeycomb structure allows the honeycomb board to have high strength while remaining lightweight.

Advantages:

1. Lightweight: Due to its hollow structure, honeycomb board is lightweight, making it easy to transport and install.

2. High strength: The honeycomb structure provides excellent compressive and bending resistance, resulting in high strength.

3. Environmentally friendly: The main material of honeycomb board is recyclable paper, making it eco-friendly.

4. Good sound and heat insulation: The hollow structure of the honeycomb board offers excellent sound and heat insulation properties.

Disadvantages:

1. Poor moisture resistance: As honeycomb boards are mainly made of paper, their moisture resistance is relatively weak, making them unsuitable for damp environments.

2. Average wear resistance: Compared to other panel materials, honeycomb boards have weaker wear resistance.

3. Complex structure: The production process of honeycomb boards is relatively complicated, which may affect production efficiency.

Common Applications: Honeycomb boards are widely used in furniture manufacturing, display panels, partition walls, packaging materials, building structures, and other areas. Due to their lightweight and high-strength characteristics, honeycomb boards are especially popular in the transportation and construction industries. However, because of their poor moisture resistance, it is not recommended to use honeycomb boards in damp environments or outdoor spaces.

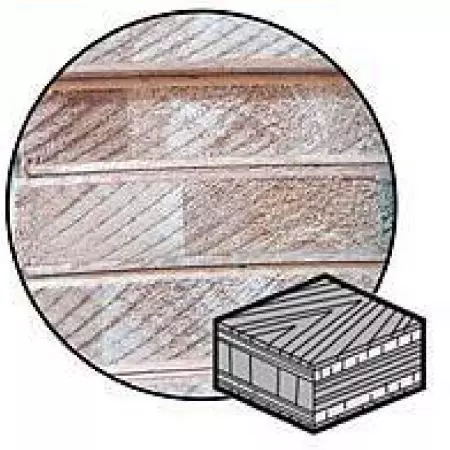

Oriented Strand Board (OSB)

Composition: Oriented Strand Board (OSB) is a type of engineered wood made from shredded wood chips (wood shavings) that are organized, directionally arranged, and then combined with synthetic resin adhesives under high temperature and pressure. This structure gives OSB high strength and stability in all directions.

Advantages:

1. High strength: The structure of OSB provides it with high compressive and bending resistance.

2. Good stability: Due to the directional arrangement of the wood chips, OSB has good dimensional stability and resistance to deformation.

3. Environmentally friendly: OSB utilizes waste materials from the wood processing industry, reducing dependence on raw wood and making it more eco-friendly.

4. Cost-effective: Compared to other types of wood panel materials, OSB offers a higher cost-performance ratio.

Disadvantages:

1. Limited aesthetics: The appearance of OSB may not be as refined as other types of panels and may require additional decorative treatments.

2. Average moisture resistance: Compared to other wood panel materials, OSB has poorer moisture resistance.

3. May contain harmful substances: The synthetic resin adhesives used in the production process may contain harmful substances such as formaldehyde, which can have an impact on the environment and human health.

Common Applications: OSB is widely used in building structures, furniture manufacturing, flooring, roof framing, and interior and exterior decoration. Due to its high strength, stability, and cost-effectiveness, OSB is popular in the construction and furniture industries. However, it is important to choose products with low formaldehyde emissions to reduce the impact on the environment and health.

High-Pressure Laminate (HPL)

Composition: High-Pressure Laminate (HPL) is a durable decorative panel made by impregnating multiple layers of kraft paper or other paper-based materials with phenolic resin and/or melamine resin, followed by stacking and pressing under high temperature and pressure. The surface typically features decorative patterns or colors and may be specially treated to enhance its durability.

Advantages:

1. Wear and scratch-resistant: HPL surfaces are hard and resistant to wear, making them suitable for high-traffic applications.

2. Waterproof and moisture-resistant: Due to its good sealing performance, HPL has waterproof and moisture-resistant properties.

3. Stain-resistant: HPL surfaces are easy to clean and have good stain resistance.

4. Rich decorative effects: HPL offers various color and pattern choices, catering to diverse decorative needs.

Disadvantages:

1. Higher cost: Compared to other decorative panels, HPL is more expensive.

2. More complex installation: Installing HPL requires professional skills and higher precision, making it more complex than other types of decorative panels.

3. Difficult to repair: Once damaged, repairing HPL can be challenging.

Common Applications: HPL is widely used in furniture manufacturing, cabinets, countertops, office desks, wall decorations, flooring, and bathroom partitions. Due to its wear resistance, waterproof properties, and rich decorative effects, HPL is popular in furniture and interior decoration.

Phenolic Compact Laminate (PCL)

Composition: Phenolic Compact Laminate (PCL) is a sturdy building material made by impregnating multiple layers of kraft paper (or similar paper-based materials) with phenolic resin, followed by stacking and pressing under high temperature and pressure. During the pressing process, the surface layers typically use decorative papers containing melamine resin to enhance their durability and aesthetics.

Advantages:

1. High strength: PCL has high compressive and flexural strength, suitable for bearing large loads and long-lasting applications.

2. Water and moisture-resistant: PCL has excellent waterproof and moisture-resistant properties, making it suitable for damp environments.

3. Wear and scratch-resistant: The surface is hard and resistant to wear, making it suitable for high-traffic applications.

4. Fire resistance: PCL offers some fire-resistant properties, increasing safety.

5. Heat and impact resistance: PCL has good resistance to high temperatures and impact.

Disadvantages:

1. Limited patterns: Compared to other decorative materials, PCL offers fewer patterns.

2. Higher cost: Compared to other types of panels, PCL is more expensive.

3. Lacking decorative effects: Although the surface features decorative papers, its decorative effects may be somewhat inferior compared to other decorative materials.

Common Applications: PCL is widely used in public spaces, such as bathroom partitions, washbasins, reception counters, display cabinets, office desks and partitions, kitchen countertops, and vanity tops. Due to its high strength, water resistance, and wear resistance, PCL is popular in these applications.

Polyvinyl Chloride Foam Board (PVC Foam Board)

Composition: PVC foam board is a lightweight panel made from polyvinyl chloride (PVC) through a foaming process. Its thickness usually ranges between 3 and 5 millimeters.

Advantages:

1. Lightweight: PVC foam board is lightweight, making it easy to transport and install.

2. Waterproof: PVC foam board has excellent waterproof properties, making it suitable for damp environments.

3. Corrosion-resistant: It has good resistance to chemicals such as acids and alkalis, making it less prone to corrosion.

4. Pest-free: The material is less likely to attract pests, reducing maintenance costs.

5. Easy to clean: The surface is smooth and easy to clean.

6. Easy construction: It is easy to cut, drill, and process, making construction convenient.

7. Low thermal conductivity and high insulation: PVC foam board has good thermal insulation and heat resistance properties.

8. Long-lasting: It is highly durable and can be used for an extended period.

9. Good sound insulation: PVC foam board offers a certain level of sound insulation.

Disadvantages:

1. Lower structural strength: Compared to other panels, PVC foam board has lower structural strength and limited compressive resistance.

2. Relatively higher cost: Compared to other types of panels, PVC foam board is more expensive.

3. Lower flexural strength: Due to its lightweight structure, PVC foam board has relatively lower flexural strength.

Common Applications: PVC foam board can be used in applications such as shower cabinets, sink cabinets, interior building walls, and raised floors. Due to its waterproof, corrosion-resistant, and lightweight properties, PVC foam board has broad application prospects in these areas.